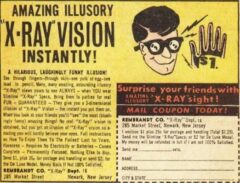

A couple of years ago, (the first time I heard about flexographic “transparent” inks being used to print corrugated boxes), I flashed back to the 60’s. On the back of almost any comic book, you would find ads for all types of gimmicky items including X-ray Glasses, Sea Monkeys, and Invisible Inks. The inks I am referring to in this post are not invisible, but they are transparent and can have a great and positive effect on your e-commerce boxes.

would find ads for all types of gimmicky items including X-ray Glasses, Sea Monkeys, and Invisible Inks. The inks I am referring to in this post are not invisible, but they are transparent and can have a great and positive effect on your e-commerce boxes.

What are flexographic transparent inks?

The best definition I’ve heard is from the Dictionary of Marketing Terms.

Transparent Ink: ink used in printing that allows the color of other inks layered under it to show-through. Transparent ink is used in four-color process printing that reproduces all the colors of the original image by printing two or three primary colors in layers.

The practical description and problem is that there are times when printing one color over another, it is possible, if not probable that the under-layer color will peek through the over layer.

A great example is the very popular combination of yellow and black overlapping each other. The conventional approach is to print the lighter color (yellow) first and then print the darker color (black) over it. However, tiny dots of the yellow are usually seen peeking through the black ink. The same would apply to orange and black, or pink and brown. Basically, overlapping any two colors can create a problem.

Here are a few ways we can use transparent inks to help you produce the best possible printing on your e-commerce packaging:

Eliminating halos, shadows and ink traps

Printing a two-color design often meant having to separate the two colors to avoid overlap and creating a third, usually unattractive color. Another option is to allow a slight overlap, if you are able to hold registration and avoid creating a gap between the two colors. That overlap is likely to create a halo, shadow or ink trap as shown in the photo below showing a very light green combined with a medium blue. If the darker blue was printed first, and the light green was overprinted with transparent inks, it would have created a cleaner, no halo, look.

Printing a two-color design often meant having to separate the two colors to avoid overlap and creating a third, usually unattractive color. Another option is to allow a slight overlap, if you are able to hold registration and avoid creating a gap between the two colors. That overlap is likely to create a halo, shadow or ink trap as shown in the photo below showing a very light green combined with a medium blue. If the darker blue was printed first, and the light green was overprinted with transparent inks, it would have created a cleaner, no halo, look.

Reducing ink rub off

You may have handled a box that was printed in a dark color flood coat, and experienced some ink rub off on your hands or even on your clothing. Colors like black, brown or even green are most likely to cause this problem because they are heavy with pigments, and in the worst case, even the product being shipped can get smudged with a dark interior color printed. A layer of a transparent color can act like a varnish, sealing the ink color underneath and improving the overall look as discussed in the two final points below.

Adding depth to a graphic design

Overprinting with one or more layers of transparent ink can make the right graphic design “pop” and in some cases, produce a 3-D look. Taking advantage of this underutilized capability can help you stand out from the competition in more ways than one.

Enhancing the color hue and brightness

The photo below does not do it justice but a layer of transparent brown, printed over a base coat of black, results in an incredibly “rich” black. A combination of two different inks can help you create effective, unique graphics.

Are transparent inks right for your e-commerce box?

They could be and we can quickly determine whether or not there is a benefit to your packaging graphic design. One of the things customers appreciate is that transparent inks do not cost more so there is not a good reason not to use them when possible.

Call us at 630-551-1700 or contact us through this web site. Much like any other tool or capability, transparent inks can do great things in the right hands. As a leader in e-commerce packaging, with over 17 years’ experience, we can confidently say the right hands are ours.

Related posts:

https://www.salazarpackaging.com/e-commerce-packaging-drivers-wanted/

https://www.salazarpackaging.com/consider-flexo-printing-for-your-custom-boxes/

https://www.salazarpackaging.com/free-inside-print-on-e-commerce-boxes/