The convenience of buying clothing via the web is obvious since it is essentially a store that is open 24/7. Consumers...

Sustainable Perspective

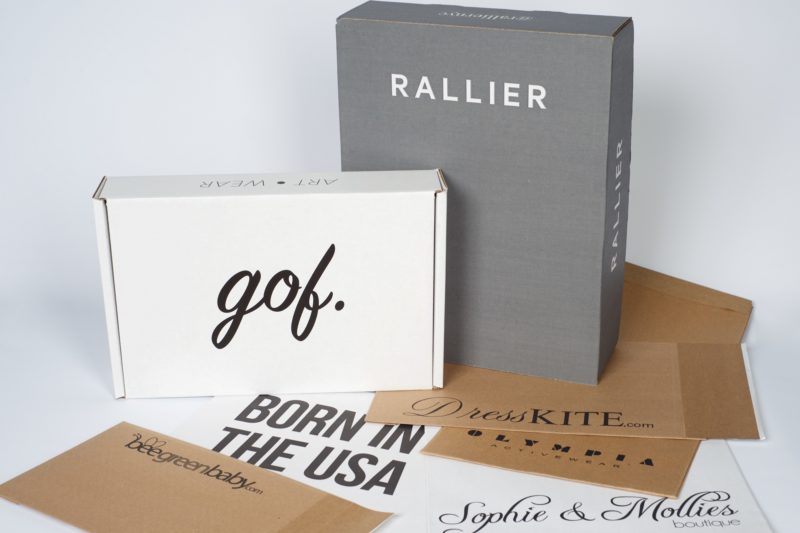

E-Commerce Boxes with Screen Printing Can Be Dazzling!

A quick stroll through our Salazar Packaging gallery will show the number of great looking boxes we have helped create...

Crate Joy’s “Subscription School” Interview with Salazar Packaging

From the inception of our company in 2007, we have strived to be a leading resource to anyone interested in launching...

Cost Estimates for Custom Printed E-commerce and Subscription Boxes

We receive a lot of inquiries and most of them are looking for a “ballpark” price for the custom printed mailer box...

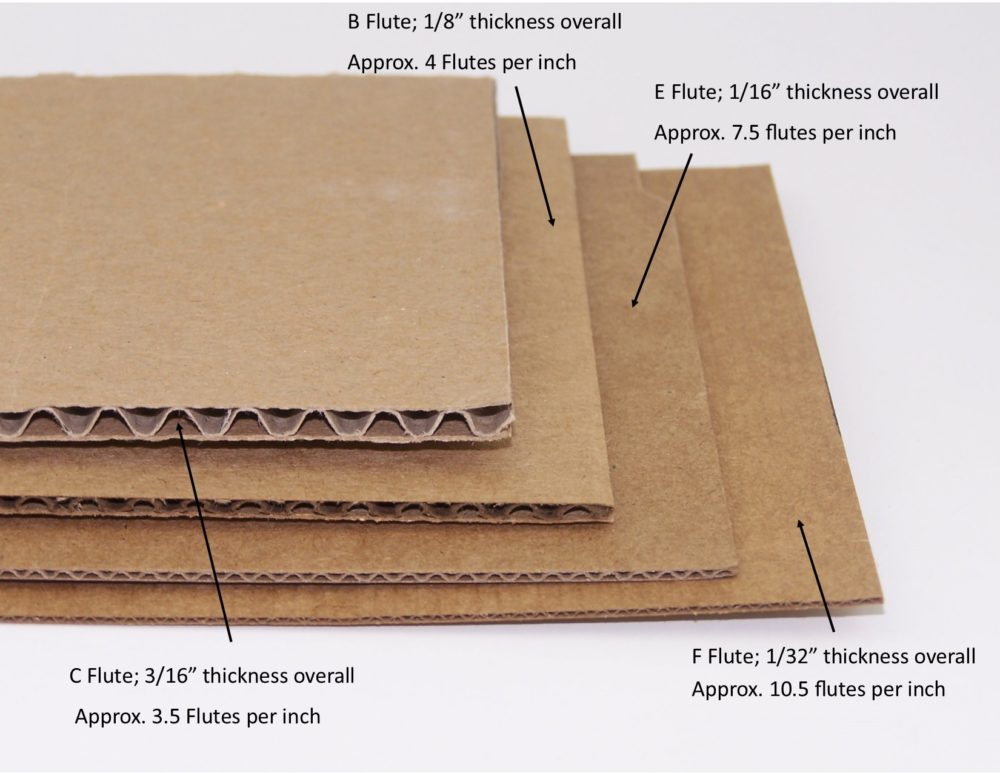

How to Reduce Shipping Weight and Cost

As a result of dramatically increased shipping rates and costs, many shippers today are looking for ways to reduce the...

Litho Labels – Another Salazar Packaging Custom Solution for Exceptional Printed Boxes

We are widely known for the beautiful custom printed boxes we help our customers create. We have become very...

What’s Your Price for Custom Printed Boxes?

It is a common web inquiry or the opening question by someone calling our office. I often joke that is much like...

Escape Monthly – New Subscription Box program with a great twist and unique packaging!

We have been very fortunate to work with a number of great subscription box programs and the most recent one,...

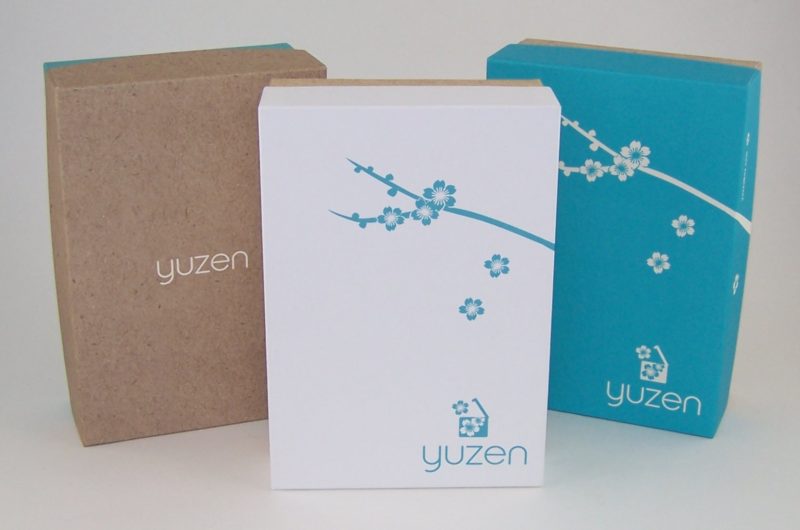

Yuzen’s Subscription Program’s New Packaging is a Sustainable and Branding Hit!

Here is a one question, multiple choice quiz for you, regarding custom printed secondary packaging: Great, branded...

Reducing Shipping Costs by Reducing Shipping Weight

Recently we have had an influx of questions and projects all related to packaging weight. Some customers have...

Custom Printed and Branded Packaging FAQ and Tips

Much of the work we do is custom printing and branded RSC shipping boxes, die cut mailer boxes, mailer envelopes,...

Good Domestic Solutions for “Bad” Imported Packaging

At the recent International Housewares Show, I had several conversations with a number of people who wanted to talk...

Bartering Organizations – The Ugly Side of Sustainability

Sustainability, when defined as something that by design reproduces itself indefinitely and never ends, is a worthy...

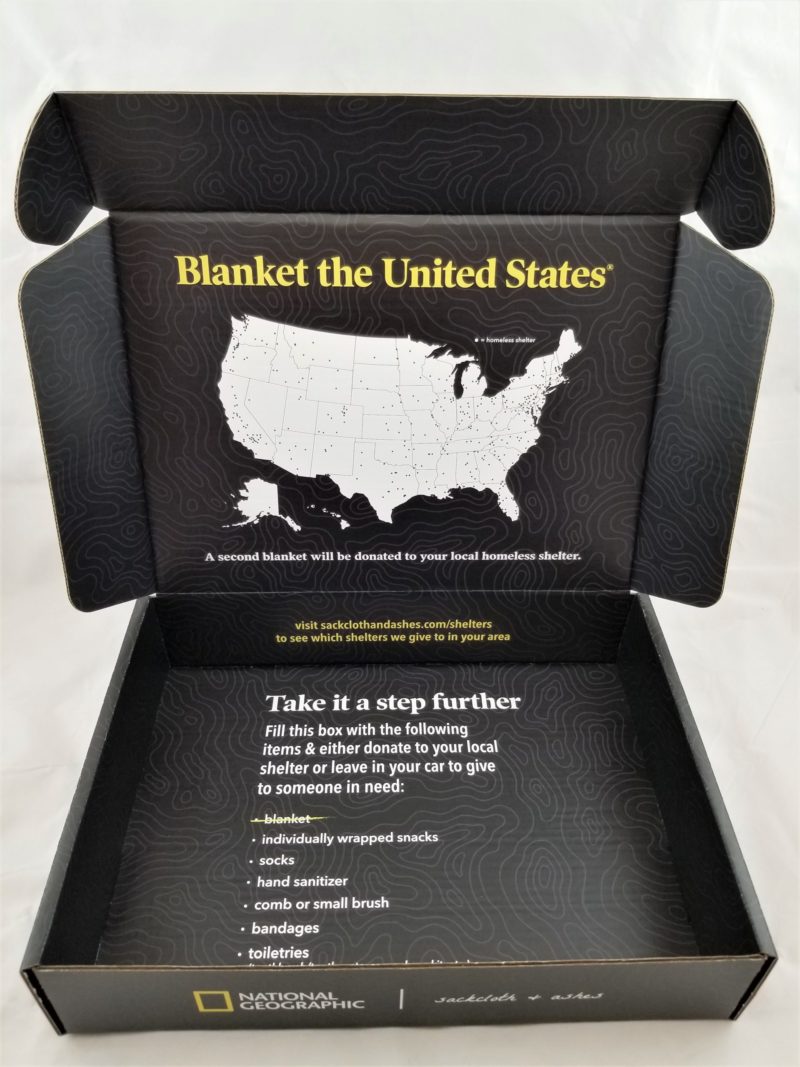

Branding and Messaging Goes Way Beyond Sustainability

Every once in a while we are involved in a packaging application that really makes us think about the non-business messaging we communicate to others. This post explores one such example.

Canon Printer Packaging – Not Eco Consistent or Up to Date

One of the things I find most interesting about sustainable packaging as well as quite frustrating at times, is that...

Hybrids Not Included – What Green Businesses Can Learn from Auto Makers

I could no longer put off a task that I enjoy almost as much as an IRS audit or root canal surgery – I had to shop for...

Let’s Talk about Sustainable Packaging

Over the course of the last three years I have been privileged to share my, at times, unusual perspective on eco...

Packaging Sustainability and Baby Steps

The nouveau green packaging industry loves to talk about biodegradability, recyclability, compostability, recycled...

Green Accountability and Visibility of Imported Reusable Bags

At a recent conference I attended as I was walking the show aisles, I was handed an “eco friendly reusable bag” by one...

The Green Get Greener with Reusable Packaging

Eco Bags is one of our newest customers but I think most would agree they are not band wagon jumpers in the area of...

Sustainable Packaging – It’s a Thing of Beauty and Health

Everything today is being scrutinized for its impact on the environment and on each of us as human beings. The old...

Happy Earth Day!

To all of our vendor friends who help us design and deliver the green packaging products our customers want and need....

Smart Green Customers Choose Globe Guard Products

A Chicago area clothing retailer had a rather catchy slogan I used to appreciate – “An educated consumer is our best...

What Is the Greatest Myth in Sustainable Packaging?

Last Sunday I had the opportunity to make a presentation and attend the International Housewares Show. It is a great...