We make millions of corrugated e-commerce boxes every year. Most people don’t realize we also create hundreds of thousands of paperboard cartons as well, many of which are also used for direct-to-consumer, order fulfillment applications. One of the many things that makes us a unique company is the fact that we work in and are well versed in both substrates, providing creative options for our clients and customers.

The Difference Between Corrugated and Paperboard Packaging

The Difference Between Corrugated and Paperboard Packaging

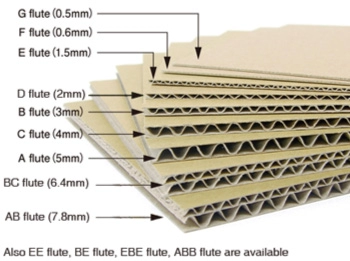

For the benefit of anyone new to packaging, corrugated is a multi-layer paper product, with a fluted (waffle looking) middle layer that is sandwiched between two outer layers of paper. A standard shipping or moving box is a good example. You can read more on that here. The thickness of the middle layer determines the box’s flute size, examples C, B or E, are the most common but there are also thinner board configurations available such as F and N, which can also be used for e-commerce. More on that later.

Paperboard has no flutes and is typically one layer of a thinner kraft or white substrate. The examples most people can relate to include a cereal box, a FedEx or UPS flat mailer envelope, or most retail shelf packaging such as personal care products.

What Board Type is Best for an E-commerce Application?

Typically corrugated is stronger than paperboard, which is the primary reason it is used for product shipment and DTC subscription boxes. The board’s multi-layer construction and flutes add rigidity making the box stronger in terms of crush resistance.

What we have discovered over the years is that many of our customers ship their boxes within another box or perhaps a mailer envelope. This is usually done to preserve the graphic design by avoiding placing labels and tape all over the outside of the box. It stands to reason, if that is how a box is used and shipped, it can probably be made from lighter, thinner material.

As always, there are many factors that help determine what type of board is best. A rule of thumb we use is that the taller the box, the stronger the board required. That is due to how boxes are handled through any distribution system like USPS, UPS or FedEx.

Different Print Processes and Inks for E-Commerce Packaging

Another deciding factor in substrate selection is the graphic design and number of colors being printed. Most e-commerce corrugated shippers are printed using a flexographic print process that uses water-based inks. In most cases, that limits the colors to 3 or 4 per side (in and/or out).

Depending on the complexity of the design, in some cases, upgrading the printing to a digital print or a litho label finish is required. Those ink types will vary but they are never water based so it is best to ask the question if sustainability is important.

For paperboard packaging, the most common printing method is offset litho and most inks used are petroleum based OR soy based. That is why retail, paperboard packaging typically has that nice smooth finish or gloss, for shelf display. Which ink is used, is typically determined by the equipment so do not hesitate to ask. A good supplier never minds a good question from an informed customer.

Thin, Small Flute Corrugated Board Option

Earlier in this post I mentioned thinner corrugated board such as F-flute or N-flute. These board options provide the best of both worlds in that it is a very thin, light weight board option. It is stronger than most 18pt or 24pt paperboard options, because it still features the flutes for added strength. Those same flutes are so tight, shallow and close together, that they offer a superior printing surface. Let us help you determine if this is a good option for you.

Branded E-commerce Packaging Help

Unfortunately, many people, especially those launching their first DTC shipping container, tend to make big, costly mistakes. This is often a result of not seeking expert advice or asking for help from the wrong person or company. The right packaging partner will make sure you have a clear understanding (positives and negatives) of any packaging product or design you are considering.

Everyone at Salazar Packaging is trained and experienced to help you make a packaging decision you will not regret or have to soon re-design. Contact us through this web site or call us at 630-551-1700. We look forward to learning more about your needs and project.

Related Posts

https://www.salazarpackaging.com/your-new-2023-dtc-packaging-is-waiting/

https://www.salazarpackaging.com/green-packaging-paperboard-versus-corrugated/

https://www.globeguardproducts.com/industry-experts/do-i-need-corrugated-or-paperboard-packaging/