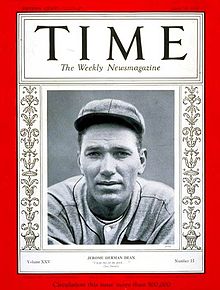

Perhaps it takes some level of audacity to refer to yourself as an expert but as Dizzy Dean, the famous Cardinal’s pitcher once said, “It aint bragging, if you can do it”.

After over forty years in the packaging industry and selling e-commerce packaging since 2007 (when most people agree e-commerce on a large scale first appeared) I can confidently say we have seen and done it all.

What we have not seen in DTC packaging

The only thing we are witnessing now that we have not seen before is incredibly high, unrelenting prices on packaging. Most paper forms of packaging, whether boxes or mailer envelopes, are a whopping thirty to forty percent higher than they were just two years ago. If your packaging is unchanged during that same period of time, you are operating at a disadvantage with a definite negative impact on your bottom line.

The number of customers and design clients who are asking for cost reduction help continues to grow rapidly. We are quick to inform them there are three basic ways to accomplish that:

1. reduce the cost of their printing

2. reduce the amount of corrugated board they are using

3. re-consider the way they are purchasing their packaging

Reduce the Cost of Your Printing

We recently reduced a customer’s cost per box by almost 30% with a change in their graphics. Their box used to feature a beautiful pastel color flood coat on the interior which was printed over white corrugated board. By eliminating the color and keeping the white board interior they eliminated the printing and reduced the cost.

Does it have the same “look”? No, probably not, but the savings was too great to ignore or pass up. Unless you are purchasing large volume quantities, printing on the inside of most die-cut mailers is costly. Reducing the percentage of ink coverage or the number of colors typically does not make a huge difference in cost but switching to a natural kraft or white from a printed interior usually saves 25 to 30%.

Let us review your current artwork and graphic design. Chances are, there is a way to do it at a lower cost.

Structural Redesign to Produce Savings

As I often tell customers, we (the customer and us) will be a lot smarter six months from now, than we are at pre-launch. By then we will have accumulated some data, gathered some customer feedback, and can review sales history to aid us in packaging design.

What does a most common order look like?

Has your product supplier changed your primary containers?

Has the count or configuration changed?

How can you best promote your top sellers while reducing your packaging and labor cost?

I have spoken before about how most new companies or old companies launching new products tend to oversize their boxes, “just in case.” Postage and shipping costs are probably much greater than anticipated and forecast. We have also written (see first related post below) about how your 3PL can impact your cost if your packaging is not 3PL-friendly. Six, twelve months, or two years later, you have a much better handle on where we can reduce costs and increase profits.

We understand people are reluctant to “redesign” anything because it consumes time, attention, and may require new plates and cutting dies. However, if you have survived that first tough year of business, you are in a great position to make these structural improvements. We offer a no-cost, no-obligation application review and will point out where small changes can produce great savings.

We understand people are reluctant to “redesign” anything because it consumes time, attention, and may require new plates and cutting dies. However, if you have survived that first tough year of business, you are in a great position to make these structural improvements. We offer a no-cost, no-obligation application review and will point out where small changes can produce great savings.

Modifying purchasing patterns for optimal cost reduction

Most people don’t realize in most cases ordering 2,000 boxes compared to purchasing the standard MOQ of 1,000, results in a 20% savings. When producing custom packaging, one of the key cost factors is set-up time. Once any machine is set up and running well the manufacturer is eager to offer a discount to the buyer if the manufacturer can continue running. The percentage of savings will vary but increasing order quantity will always result in a cost reduction, per box.

Another important, fast-increasing cost factor is shipping. In the last year, some freight rates have doubled or more. As we remind customers, shipping four pallets of boxes twice is a lot more expensive than shipping eight pallets one time. Anything you can do to order in bulk and avoid multiple shipments is going to save you money.

DTC Packaging Experience Makes the Difference

We produce millions of boxes every year for hundreds of customers. That exposes us to a wide variety of situations and issues, each requiring a personalized solution. Our primary objective remains to produce the most attractive and effective e-commerce packaging at the lowest possible cost. Many factors help determine how and where we can best deliver a cost reduction for our customers and clients.

Call us at 630-551-1700 or contact us via this website to speak with one of our branded packaging advisors.

Related posts:

https://www.salazarpackaging.com/packaging-triage-and-how-we-fix-what-hurts/

https://www.globeguardproducts.com/industry-experts/consider-rsc-boxes-for-packaging-cost-savings/