Even though we are now almost an 18-year-old company, my wife/partner and I vividly recall when every penny we spent was a major expense and decision. It seemed each day; we proved the well-known new business adage: “it will take twice as long and cost twice as much as you think to be successful”. So, we totally understand when new, small businesses do everything they can to save money as they build their start-up company.

However, there are many situations, when in an effort to minimize expenses, inexperienced entrepreneurs unknowingly waste precious resources and money. Here are a few of the most common mistakes we and others have made when purchasing packaging supplies, especially shipping and retail boxes:

- Avoid buying boxes that are larger than necessary.

This is by far the most common mistake, which we call the “just in case” dimensional mistake. When starting out, most companies have little or no customer purchase history to work with. So, they tend to oversize boxes for products and customers they have yet to secure. The box, tape, void fill materials are all more expensive than necessary but the largest, unexpected waste is repeat inbound and outbound shipping costs.

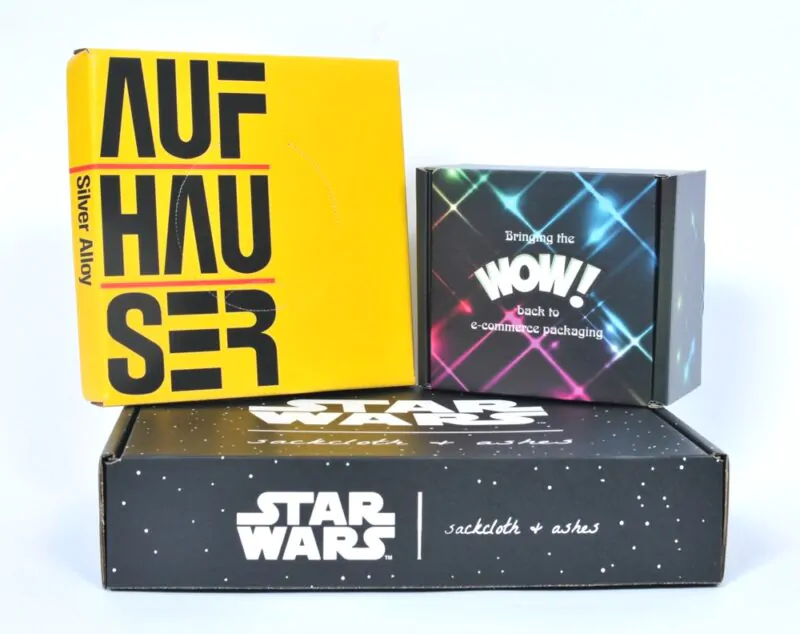

- Weigh your print process options.

We often talk about the three most popular printing methods we utilize for our customers – flexographic, digital and litho label. Each has pros and cons including distinct finished looks and of course dramatically different costs. Which is the best option for you, and where you are at? Companies like ours, who are experienced in all three print processes, will review your graphics and order size, to help you select the best option for you.

- Consider an existing box size.

Not necessarily when working with an experienced company like ours. For example, over the years we have accumulated over 250 cutting dies, including many of the most popular e-commerce sizes. Now that most cutting dies cost over $1,000 each, being able to use an available size cutting die at no cost can help make your project more affordable than you expected.

- A totally finished box is not necessary on day one.

Everyone prefers to have a beautiful, complete box for their initial launch. However, many of our customers have discovered they can grow into the box of their dreams. For example, additional color graphics, inside printing, and even protective internal packaging such as partitions, dividers and die cut inserts can be easily added after the initial run, minimizing cost when you most need the help.

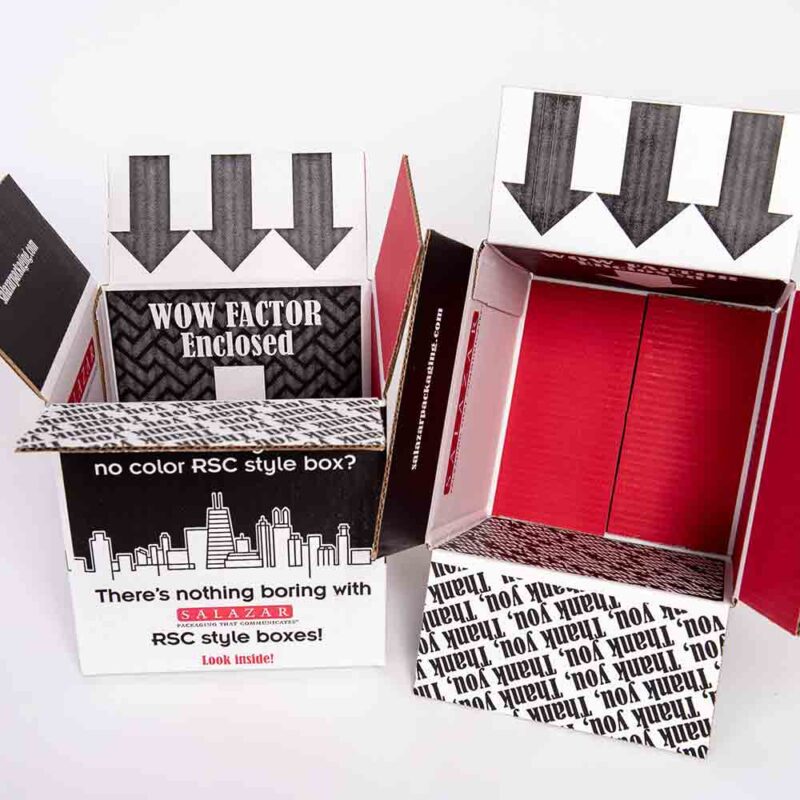

- Consider an RSC style box.

One of the best changes in the last few years is the popularity of RSC style boxes for e-commerce applications. New printing capabilities make it much easier and less expensive to create boxes with attractive outside printing AND inside printing. The first “related post” below provides details but in brief, compared to die cut mailer boxes, RSC’s can be half the cost with less expensive print plates and no cutting dies. They may be right for you, your products, and your customers. Ask us what an RSC box can potentially do for you and how much money they can save you.

Our ability to relate to new startup companies or mature companies with new product launches is because we do know the significant sacrifice and cost it takes to do it right. Many of our best and favorite customers are companies who initially trusted us with a 1,000 MOQ box order. Now those same companies are ordering truckloads. We like believing that we have contributed at least a little to their success.

Let us help you, regardless of where you are in terms of products and experience. Our goal remains, “creating the best, most attractive box at the lowest possible cost”. Call us at 630-551-1700 or contact us via this site. Our experienced team is waiting and eager to learn more about your project.

Related posts:

https://www.salazarpackaging.com/new-e-commerce-packaging-projects-wanted/