Both materials can be excellent eco-friendly packaging. Paperboard packaging is what you see on a FedEx or USPS style flat mailer envelope, or a typical cereal box. By comparison corrugated board has fluting and is what a standard brown box is made of.

Both materials can be excellent eco-friendly packaging. Paperboard packaging is what you see on a FedEx or USPS style flat mailer envelope, or a typical cereal box. By comparison corrugated board has fluting and is what a standard brown box is made of.

The line used to be fairly clear – paperboard was used for primary/retail/display packaging and corrugated was used strictly for secondary packaging such as for shipping boxes simply expected to get products from point A to point B.

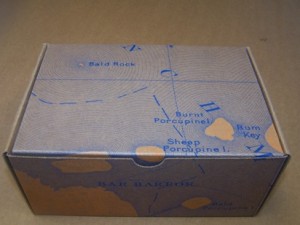

As paperboard has become thicker, while corrugated has grown thinner, and both materials are engineered better and more visually appealing, you now see paperboard being used often for shipping purposes such as in mailers, tubes and other structures. There is also growing trend to use corrugated for retail packaging for its “greener look” (see image below).

Sustainable Perception Is Sustainable Reality

It is true for most consumers and the average person believes that corrugated is a more eco friendly solution. We probably have helped to perpetuate that perception with our Globe Guard line of 100% recycled PCW corrugated products but the truth is that 100% recycled content paperboard is now readily available as well. Actually we have worked on several recent paperboard projects (primary and secondary applications) with a very good local manufacturer and we will soon be posting an interview with them here on ISP. I will allow a paperboard expert to give you his side of the eco story but here some thoughts on corrugated for retail applications you may find useful.

Is Corrugated Now Trendy?

This is hard to believe but true. There continues to be something about corrugated board that gives consumers a feeling that it is a more natural form of packaging compared to paperboard or that much maligned plastic. Perhaps it is the natural brown color of corrugated that has suddenly become an asset rather than a liability, or those intriguing little flutes that give it strength while using a minimal of paper fiber. In any case, corrugated is not just for the retail backroom anymore and often finds its way home with the consumer. That is another good reason to use the greenest corrugated available.

One of the reasons paperboard was often used in the past for retail is because it allowed for better and sharper graphics. The quality of printing on corrugated has improved dramatically and even if the buyer is not a big fan of the brown finish, it can easily be flood coated with a good plant based ink and the brown box can be transformed into an attractive, soft hue of yellow, purple or virtually any other color the marketer or designers insists on. If a corrugated design is desirable but even higher quality graphics are needed, a recyclable label can be printed and applied to achieve a unique, eye popping look.

Corrugated is an excellent solution for retail or for any product being shipped to the consumer, such as in an e-commerce application. Corrugated is strong, and can be formed into just about any design that is needed and has a definite green look that is obvious to even skeptical customers. Consider corrugated and paperboard both rated “G” for green results.