How to Reduce the Impact of Corrugated Price Increases

In my mind there is no way to justify substantial back-to-back industry price increases. One in December 2020 and now another that is sure to happen within the next 30 to 60 days. We cannot explain it but there are plenty of theories floating around ranging from reduced capacity to the dramatic increased consumption of e-commerce packaging and corrugated board.

The only thing I know for sure is that we can’t avoid or fight it, so the best thing we can do for our customers and friends is help them determine how to reduce the amount of corrugated used on a per package basis. This can help hold current costs and perhaps even show a net decrease per unit.

Less Corrugated – Less Cost

Reducing the amount of corrugated your packaging requires is just one way to reduce your overall costs and combat corrugated price increases. Other positives beyond the obvious environmental benefits are lower inbound shipping cost (to you) and lower outbound shipping costs (to your customer). One of our customers recently reduced their outbound shipping costs by over $4.00 per order by downsizing and right sizing their shipping containers. That certainly helped to more than cover the cost of the box and inner packaging we created for them.

Most of our customers utilize a co-packer, fulfillment operation, or 3PL company to do their picking and packing. Using less corrugated usually results in a more simple, compact design that is quicker to assemble and store. Since you ultimately end up paying for both, saving your fulfillment operation time can and should result in a reduced pick and pack cost.

How Can a Different Box Design Reduce Your Corrugated Usage?

There are countless types of corrugated designs and variations available out there but here are a few that may produce great savings for you:

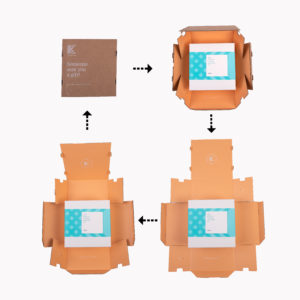

One Panel Folder – Our Ta-Da Box™ is a perfect example. The application, (in the first related post below), reduced the customer’s corrugated consumption by OVER 30%. Is it right for every application? Probably not, but when it works it is beautiful, green, and makes an amazing presentation.

One Panel Folder – Our Ta-Da Box™ is a perfect example. The application, (in the first related post below), reduced the customer’s corrugated consumption by OVER 30%. Is it right for every application? Probably not, but when it works it is beautiful, green, and makes an amazing presentation.

RSC versus die cut mailer is a sure win for RSC boxes since by their very design, have almost zero waste and can be easily and quickly modified smaller or larger to better fit and avoid oversizing. The amount of wasted board on a taller box is even more apparent as the box increases in height from 4” or more. Check out our gallery to see the great print potential, inside and outside on an RSC. (see second related post below)

An Indestructo style mailer offers big savings when compared to a standard front lock or die cut mailer. Ask us and we will share drawings showing how much less corrugated you use, and the potential savings becomes obvious. There is a reason why some companies only buy and sell the Indestructo design.

Right sizing to your current corrugated box requirements. If you are a regular reader of this blog, you know we love to write about the benefits of rightsizing. Almost a third of all boxes we see are too big for the products being shipped. It is a very quick, easy, and in most cases inexpensive change to make. Remember, we can make your boxes to ¼” size dimensions. Stop using that (stock/ standard) 10” X 8” X 4” if what you really need is 9” X 6-3/4” X 3-1/2”. The shipping cost savings as well as reduced internal void fill packaging and labor expense can be very real and easy to accomplish.

Mailer envelopes versus mailer boxes – Our custom printed DTC boxes are known from coast to coast but some of our best customers buy mailer envelopes from us. As box prices continue to rise, it is possible for many applications. A lower cost envelope could possibly eliminate a higher cost box. This includes our new paper padded mailer envelopes that are 100% recyclable at curb side or wherever paper waste is processed. (check 3rd related post below)

These are a few of the ways we can help our customers and the environment. It is wonderful when sustainability results in immediate bottom-line savings.

We’ve been doing this since 2007 so we have picked up a few tricks along the way. Try us and allow us to do a no cost, no charge, application review. We can quickly tell you whether you have savings potential and with a closer look, tell you how much.

Trust me, in the days ahead, this will become increasingly important. It is going to be a difficult 2021 in the packaging industry, but we can help you work through it. Call us at 630-551-1700 or contact us through this web site: www.SalazarPackaging.com

Related posts: