A regular reader of this blog might incorrectly believe that we are anti-3-PL. To the contrary, we believe copackers, 3PL (third party logistics) companies, fulfillment houses, etc., play an invaluable role in bringing a product, any product, to market via e-commerce.

With all due respect and appreciation, most of our customers are brilliant, product creators, and web-based marketers. However, most of them are not knowledgeable or interested in creating their own packaging operation. Not when there are so many excellent, experienced companies, who already have the facility, infrastructure, and people to do it for them.

What services do 3PL companies provide?

In short, they receive and store the products you are selling, as well as the packaging you intend to use. They can “pre-kit” your products and packaging, assembling your product configurations and combinations in advance of orders being received. Or they may pull the products and packaging from your stored inventory as needed, after your orders are received.

In addition, the 3PL may even serve as your customer service response team and handle your credit card processing. On the receiving end most provide incoming product QC, especially for shipments originating overseas. Other services provided typically include inventory management of both packaging and the products you sell.

How does your packaging design impact your 3PL costs?

Unfortunately, you may not have that answer until it’s too late. We’ve seen too many companies not have firm 3PL pricing until their packaging is designed and possibly produced. If the customer/brand owner and quite frankly, the company designing the packaging do not have the experience needed, the packaging provided may substantially increase the overall fulfillment cost.

How can this be, you may ask? For example, the brand owner customer may meet with a 3PL and tell him they are providing die cut mailer boxes with an insert that will provide separation for the four identical products being shipped together. The internal and external packaging arrives, and it is determined the insert is much more complicated and has more components than anticipated. With extra scores, flaps, and folds, the new design will require more time than originally estimated, or budgeted for.

How can a packaging designer save or cost you money?

Here are a few of the most common ways we have seen after seventeen years and working with thousands of customers.

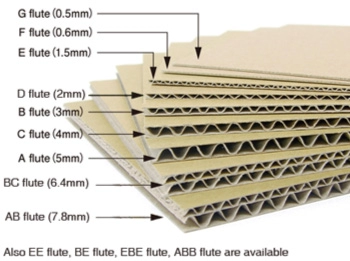

Box board thickness – will determine how many boxes or inserts you can place on a pallet to be shipped into the 3PL for storage. Since storage cost is calculated on a per pallet basis, the more packaging components you are able to place on a pallet, the lower the storage cost for each. Boxes and inserts that are made with thicker board than is truly necessary, will also be harder to fold, decreasing productivity and increasing time and cost.

Overly complicated structural designs are expensive to use – Assembling your packaging consumes time so you must determine whether or not the design you use has too many scores or components. That is why many 3PL companies charge assembly “per score” so a box that has excessive scores (folds or bends) will be billed at a higher cost. Our designs always utilize the age-old KISS method: Keep It Simple Stupid. Understanding the potential 3PL costs, we minimize a design in terms of board square inches, but also in terms of how easily it will be assembled. Keep in mind, this also makes it easier for your customers to open their box when received.

How a box is sealed makes a cost difference as well – plastic tape, paper water activated adhesive tape, or peel and seal adhesive designed into the packaging can also determine how long it takes and how easily an order can be completed for shipment. We typically recommend plastic tape closure, especially on a smaller box. On a larger box, custom printed paper tape can be a great way to reinforce your brand.

Box size can add cost, well beyond the price of the box – The most obvious way a box size and impact cost are inbound shipping (from supplier to you or your 3PL) and outbound shipping to your customer. By our estimate, over half of all e-commerce shipping boxes used are larger than they need to be. That is not just what companies like Target, Amazon, and Staples do, smaller companies are guilty as well. Your order size and product sizes may have changed so let us help review what your business is today, and we can help you adjust your packaging if that is appropriate.

There are many potential problems and cost-reducing solutions for your DTC packaging. Please feel free to contact us through this site or call us at 630-551-1700 for a no cost, no obligation, application review. If we can’t help you reduce your costs, we will tell you, but those situations are very, very, rare.

Related posts:

https://www.salazarpackaging.com/4-ways-to-know-you-need-a-new-packaging-supplier/

https://www.salazarpackaging.com/e-commerce-packaging-structural-versus-graphic-design/