We are widely known for the beautiful custom printed boxes we help our customers create. We have become very proficient at utilizing the standard flexographic print process to its maximum potential to produce unique, eye catching and colorful results. However, what happens when flexographic print process is not enough? What do we do when the customer wants something that is completely out of the ordinary? That is when a little known process called litho labeling can deliver results not possible on a standard flexographic press.

The Limitations of the Direct Print Flexographic Process

You can get more info from the first listed “related posts” below but flexographic corrugated printing is a “direct print” process. We apply the ink directly onto the corrugated board utilizing flexible print plates.

Corrugated board is an industrial grade paper, NOT a fine printing paper as you might see on a brochure or even on a paper board box. The board surface and porosity of corrugated paper is going to differ from that of fine paper, making it impossible to create identical results. This is most obvious on color consistency, especially on dark, high ink percentage colors.

In addition, for each color that is going to be printed a flexographic press requires an individual print plate that typically costs between $400 and $600 per color. That makes 4, 5 or more color work very expensive in terms of initial costs, especially if you need for example, packaging for multiple colors, flavors or products.

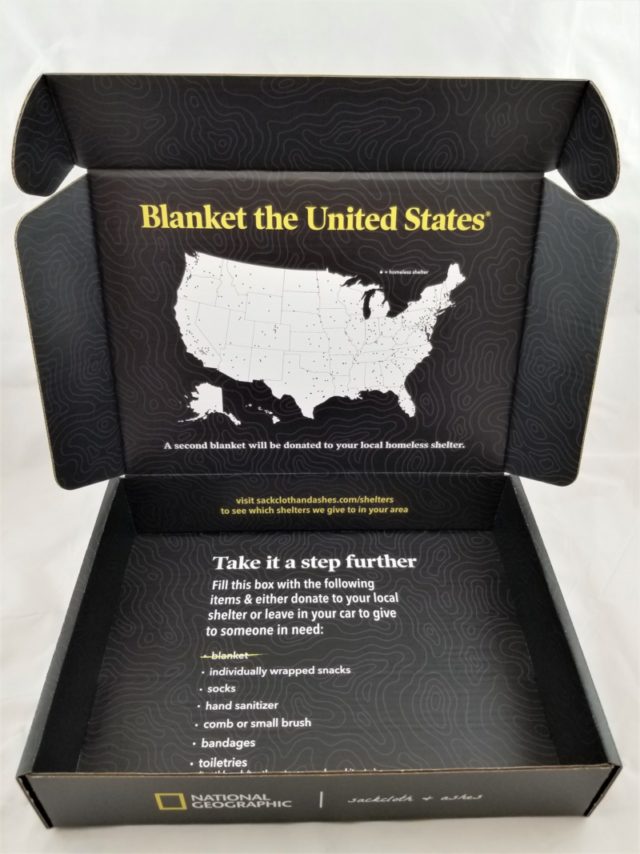

The litho label process is completely different because it is NOT direct. We print customer copy using an offset lithography process onto fine “litho” paper which is later laminated to corrugated board, before the board is cut or converted into boxes.

This permits truer colors, multiple shades and even different types of varnishes and finishes. Sharp vibrant colors become easy and photo quality images are possible. This can make art much more effective in terms of pop and sparkle for retail and/or premium shipper applications.

What is the down side of litho labels? Quite frankly because of the multiple step process, they can be quite expensive, especially on short runs. While we routinely run 1,000 minimums on our flexographic print jobs, we rarely can consider a litho run of less than 5,000 and it really becomes much more affordable at 10,000 or 20,000. Several factors come into play including box/label size but we can quickly help you determine if litho labels are a viable option for you.

Combining Litho Labels and Direct Flexographic Print

Combining Litho Labels and Direct Flexographic Print

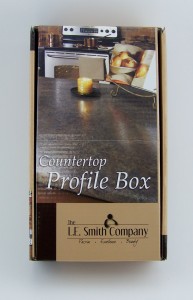

Litho labels are not an all or nothing graphics option. Another, less expensive creative approach is a partial or spot label that can be very effective, especially when it is combined with direct print on the same box. This provides great flexibility and terrific appearance at the lowest possible cost when constant information can be direct printed and product specific labels showing off styles or color photos can be added to help shoppers distinguish product on the shelf.

Please contact us at Salazar Packaging for a confidential application analysis to determine the best way to help you accomplish your branding and cost objectives.

Related posts:

https://www.salazarpackaging.com/sustainable-packaging/the-truth-about-custom-printed-boxes/