Too Much Packaging!

The nouveau green packaging industry loves to talk about biodegradability, recyclability, compostability, recycled content, PLA, PCW and a constantly growing variety of green acronyms. They are also just as eager to debate which product or process is best for the customer and for the environment.

We ourselves are helping to lead the charge on reusable and recycled content packaging products but often times we all over look the easiest sustainability “R” of all and that is reduce. Packaging reduction opportunities are usually very simple to identify and almost always even easier to correct.

A Perfect Example – A Recent Shipment from Zappos.com

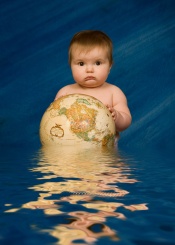

Zappos.com is a terrific company and one of my personal favorites but the recent order (photo) we received from them caught my attention. The box they used to ship our order of baby shoes is obviously more than two times larger than it really needed to be.

To be fair, it could have been almost any internet retailer, shipping almost any order and most of them are indeed guilty of this same sustainability crime. I realize it is possible the packer simply selected the wrong size box but having reviewed and assessed many order picking and packing stations; I know the correct size box is usually not available for the packer to utilize.

“Use the smallest box available” is the common direction a packer receives but the smallest box available is frequently not the right size for the application and product being shipped. Using an oversized box obviously adds packaging material cost as well as much more difficult to calculate costs such as storage space, shipping cube space, fuel costs, load inefficiencies, etc. Perhaps even more important, it just plain looks wasteful to an ever vigilant eco conscious consumer.

Keeping Up and Staying Green with Changing Customer Needs

Monitoring how customers buy is a never ending process, especially in e-commerce where packaging and shipping is such a crucial portion of the order processing cost. Primarily due to the economy, most analysts will agree customers are ordering in smaller quantities and more often. ISP offered a post two months ago on this very topic.

Monitoring how customers buy is a never ending process, especially in e-commerce where packaging and shipping is such a crucial portion of the order processing cost. Primarily due to the economy, most analysts will agree customers are ordering in smaller quantities and more often. ISP offered a post two months ago on this very topic.

Adjusting your packaging and box sizes to accommodate these smaller orders makes economic and environmental sense. In the case of Zappos.com, how often do customers now buy just one pair of baby shoes at a time? Has that changed over time? What is the percentage of the overall total? Does the volume justify the addition of a new, smaller shipping box? Add to this the fact that most people who order baby shoes are probably in their twenties and thirties, an age group who is passionately green and scrutinize everything for its relative greenness.

Good Fit Is as Important as Good Looks

You’d think anyone in the shoe business would understand that. I see a Zappos.com box and have to question why it has to be white. After all, they are not in the medical, pharmaceutical, or even meat packaging industry, so why use boxes that are white on the outside and require the use of virgin paper?

White boxes are likely to look even more beat up and scuffed upon their arrival, compared to brown boxes, and as much volume as Zappos.com does, they could save a lot of trees if they opted to use natural Kraft colored shipping boxes. Of course, they could save even more trees if they utilized a 100% recycled content or 100% PCW box but a good start or baby steps in the right direction, would be using the correct size shipping box.

Remember, “right sizing” applies to packaging as well as shoes.

______________________

Visit the Globe Guard ® Green Packaging Store for –

Visit the Globe Guard ® Green Packaging Store for –

Green Shipping Boxes

Eco Friendly Packaging Materials

Discounts on Eco Friendly Shipping Supplies

Learn more about the Globe Guard ® Resusable Box