We are very fortunate to work with many new companies or companies with new products requiring green packaging. In many cases however the initial run is relatively short and when or if the job will ever run again is unknown. We also have a number of clients who do promotional type work who know their job is never going to repeat.

Biggest packaging hurdles and expenses – Plates, dies and set up costs

It is not unusual for a tooling and plate cost to run into thousands of dollars depending on the type of print, number of colors and the design of the package being run. That makes it cost prohibitive for many companies, so they resort to labels or other ways of branding their products. The end result often times puts them at a competitive disadvantage in terms of package appearance when consumers are comparing their product to others on the retail shelf or over the internet.

The other factor that comes into play is set up costs and that is what usually makes short runs so expensive. It is the combination of expensive plates, tooling and long set up times being amortized over smaller quantities. Keep in mind the set up time for two thousand printed shipping or retail display boxes is virtually the same as for a two million piece job. Unfortunately the end result is that the highest per unit prices are being paid by the companies who can least afford them.

Digital printing on almost any packaging substrate

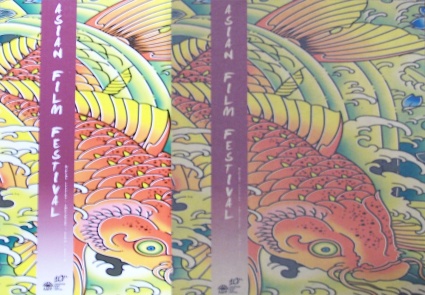

Almost any grade or type of plastic or paper material can be digitally printed with virtually any copy and number of colors. Plastic substrates can include polyethylene, polypropylene and even foam board. Paper substrates can be any grade of paperboard or corrugated and they can be printed on white for sharper colors or on natural brown for a more muted effect and a greener end result. The image below shows the difference. While the poster version on the left is brighter, the softer tones on the right are very popular and desirable today for green products and consumers.

Left: Printing on white board. Right: Printing on brown board.

Once printed, the substrate can usually be cut and formed into almost any shape. A die can be created when the cost is necessary and warranted or small quantities can be manually cut on a table.

Eye Catching Green Packaging Design

That great five color design you and your graphic artists came up with is now affordable. Suddenly running as few as two digitally printed boxes for a show or photo shoot is possible and economically feasible.

What this new capability does for our clients is give them flexibility and options that were impossible or at least unaffordable before. This also enables them to compete with almost any other company in their market and not be at a distinct disadvantage in terms of appearance or image.

Is digital printing right for you and your situation? Allow us to help review it as one possible option in a long list of Salazar Packaging and Globe Guard solutions.

______________________

Visit the Globe Guard ® Green Packaging Store for –

Visit the Globe Guard ® Green Packaging Store for –

Green Shipping Boxes

Eco Friendly Packaging Materials

Special Deals on Eco Friendly Shipping Supplies