Staples Packaging Leaves Much to Be Desired

Earlier this year, January 13th to be exact, I posted an article complaining about some very eco unfriendly secondary packaging I had received from one of our favorite suppliers, Staples.

Large retailers often appear to be leading the green charge so the interest level they create is usually high and this was no exception. The post was soon picked up by Green Biz and other eco focused blogs and I even contacted them on at least two occasions and offered my services at no cost so I could help them determine where Staples’ in house fulfillment “eco system” is obviously broken.

I was told they were “working on it,” so as a loyal customer concerned about their secondary packaging as well as the environment, I waited, and waited until this week when we received delivery of an order we placed for two boxes of ink cartridges.

Staples Green Update – More Green Packaging Problems

The photo above show the two boxes of Canon ink cartridges which shipped from two different Staples facilities. I appreciate the fact that the order was split-shipped to be filled quickly but I find I hard to believe that neither facility had both items. I am not sure what type of carbon footprint that creates but the worse news is that each facility used a different way of packaging the product and neither passed the green test as far as we are concerned. The term one step forward and two steps backwards comes to mind when we compare it to the packaging described in our January blog post.

Package #1 Shipping from Beloit, WI

At this Staples distribution center the packer opted to use a plastic mailer envelope. Even though I don’t like flexible mailers for crushable product, I am generally a big proponent of mailer envelopes, plastic and paper. I like them because they are light weight, can be made of recycled content and in most areas may be recycled for creating more packaging or other plastic products. However, the mailer that Beloit used did not indicate any recycled content, and did not even offer a recycle code for handling the waste after use.

This is a real shame considering some of the new plastic mailers that are available. We offer several that would be better eco options than what was used on this shipment.

Package #2 Shipping from Carol Stream, IL

At this facility they used a 13” long X 10” wide X 5” box (650 cubic inches) to ship a 4” X 2.25” X 2.75” product, or about 25 cubic inches, which is obviously much more box than was necessary.

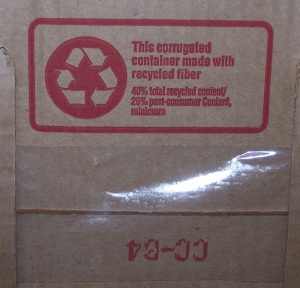

Back in January I was critical of the box they used because it contained “40% total recycled content/25% post consumer content, minimum” and I urged Staples to consider using a box that offers a greater PCW content. Perhaps I should have left well enough alone because the box we received made no mention of recycled content at all.

For void fill they used three 24” X 36” sheets of low grade news print paper which is a good green void fill product. I am going to assume they used newsprint because the product being shipped was light and the void would have required an excessive amount of any inflatable void fill. I hope they did not miss the point I made last January that inflatable void fill can be a good eco friendly void fill product but the right composition and manufacturer must be used.

Ten Months Later

Compared to the box I wrote about last January, and several we have received since, this particular box received was not an auto bottom box but the current box was still sealed with multiple strips of 3” case sealing tape. That is still way too much tape for the application and contents. Typically this is a result of an attempt to reduce tape cost but it has the opposite effect when the packer requires and uses more tape.

Ironically, on the plus side, we noticed the box thickness was downgraded to 26 ECT construction which is probably all that this application required. I would like to think that was a green move but my guess is that it was strictly a cost saving decision because Staples is doing good in some ways but not in many others.

The Reality of Green Secondary Packaging

The part that really bothers me about a situation like this is that corrective sustainable measures are not expensive; in fact we have proven over and over again that they typically net out at a reduced cost. Unlike working to accomplish sustainability in an area such as building operations, this work does not cost money or take long to implement. The right products, a little bit of training and companies like Staples, could easily and quickly be even greener at every customer point of contact.

Mediocre Green Shipping Boxes in January, 2009

Worse Green Shipping Boxes in October, 2009