We have quickly become one of the leading suppliers of custom printed die cut mailers in the country by reducing our minimums, simplifying the process and making custom branded boxes possible and affordable for just about anyone.

However, what happens when a stock mailer size or design is NOT the right or best solution? In those rare scenarios, we understand the subtle design differences that can make a die cut mailer perfect for your application or a nightmare.

All die cut mailers are NOT created equal

Aside from more obvious differences like board grade or board color (usually white or natural brown Kraft), the way a corrugated mailer is designed can make a tremendous difference in the way it performs for you.

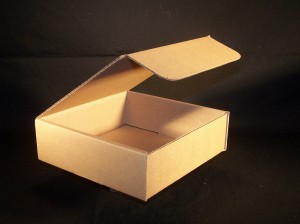

This post includes photos of three mailers that are identical in size with inside dimensions of our stock 7-1/8” X 7” X 2-1/4” high. However, each of the three boxes shown feature slightly different designs, each with distinct advantages and disadvantages.

Is by far the most basic form of a die cut mailer and features a lid that folds “inside” the frame of the box. It is easy to erect, and can be sealed with a strip of tape across the front upper edge or with the shipping label. It is also relatively economical and as an example, the design shown in the photo used 372 square inches of corrugated.

The disadvantages are that in some situations you may not want the lid to fit inside the box. For example if the contents are loose items or if the contents are a tight fit. The other potential problem is that because of the top side openings, it may be perceived as less secure.

The front lock mailer overlaps the front of the box and provides locking tabs that help hold the lid closed, making it the most secure option. Since the front of the box slips over the front panel rather than inside the box, it is less likely to interfere with packing materials or the products being shipped.

One of the most popular options with this design are the “dust flaps” or wings that do fit inside the box but fully enclose the contents, especially if they are small, loose items. That is the primary reason we choose this design when we recently added our 5x4x3 and 8x4x3 front lock mailers to our stock list.

The disadvantages of this style of mailer box are that it takes a little more time to erect and uses slightly more board. In this case on the same identical size as above, this design used 408 square inches of corrugated.

“Pizza Box” Style Corrugated Mailer

The pizza box design is unique in that the back panel unfolds and opens up, permitting easier removal of the contents. That is an obvious advantage if the contents happen to be a hot pizza (hence the name) or a solid product that intentionally fits snuggly in the mailer. This “open back” can turn into a disadvantage if the products being shipped are loose and likely to roll or fall out of the back of the box when it is opened.

It is by far the most economical design option and our box with identical inside dimensions consumed only 300 square inches of corrugated which is a substantial corrugated reduction and cost savings.

RSC and die cut mailer boxes that are “green by design”

Our Globe Guard 100% recycled content mailers are green because of the board we use as well as the designs we utilize. You can see the impact these design variations have on assembly, packing, corrugated usage and even potentially on shipping costs.

The key is to use the right container for the right application. We can help you accomplish that with a simple, quick, review of your specific needs. Please contact Salazar Packaging for your custom size, custom design and custom printed corrugated box needs.

Related posts:

https://www.salazarpackaging.com/sustainable-products/green-shipping-boxes/

https://www.salazarpackaging.com/sustainable-packaging/when-custom-packaging-can-save-you-big-money/

https://www.salazarpackaging.com/sustainable-packaging/custom-printed-stock-mailer-boxes-faq/