by Dennis Salazar | Feb 5, 2015 | Inside Sustainable Packaging

The Common and Uncommon Box Sizes of Semi-Custom Branded Packaging A quick visit through our green packaging store or our gallery will show you some of the most popular sizes we have for subscription and e-commerce applications. The available sizes include but are not...

by Dennis Salazar | Oct 1, 2014 | Sustainable Perspective

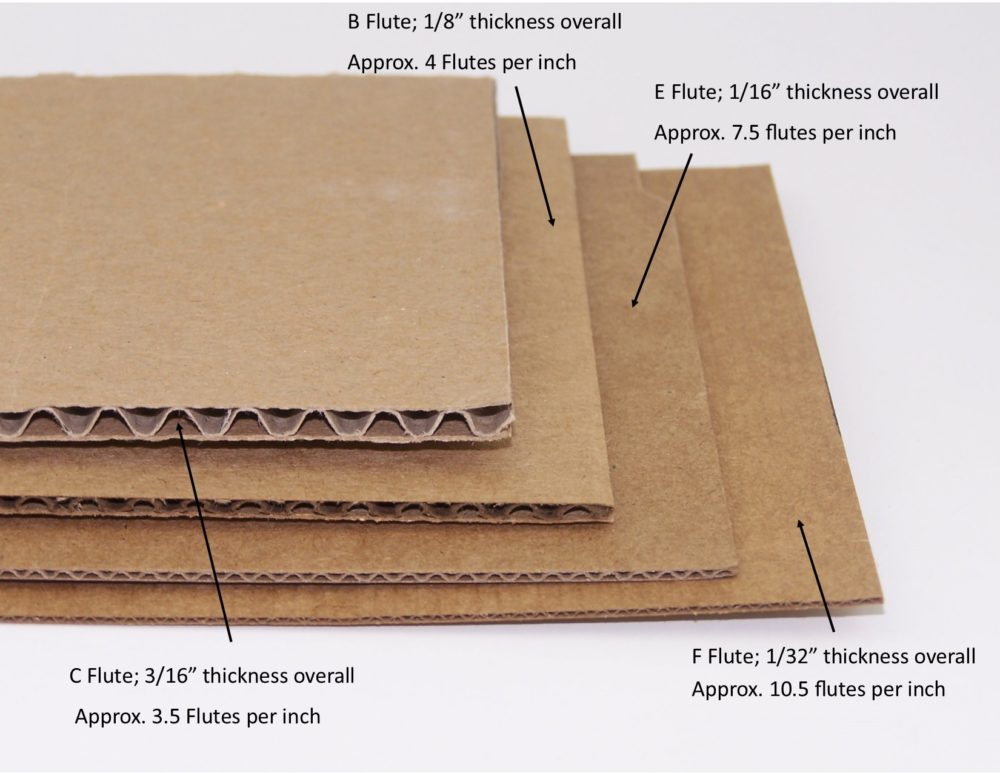

As a result of dramatically increased shipping rates and costs, many shippers today are looking for ways to reduce the overall package weight in an effort to reduce the shipping cost. Being over or under a particular weight (for example, one pound) can make a shipping...

by Dennis Salazar | Aug 29, 2014 | Sustainable Products

Most of our best blog posts are a result of great questions asked by active and potential customers. Our thought has always been, if one person out there is wondering about this, there are likely others with the same question or concern. This is one of those posts...

by Dennis Salazar | May 30, 2014 | Inside Sustainable Packaging, Sustainable Products

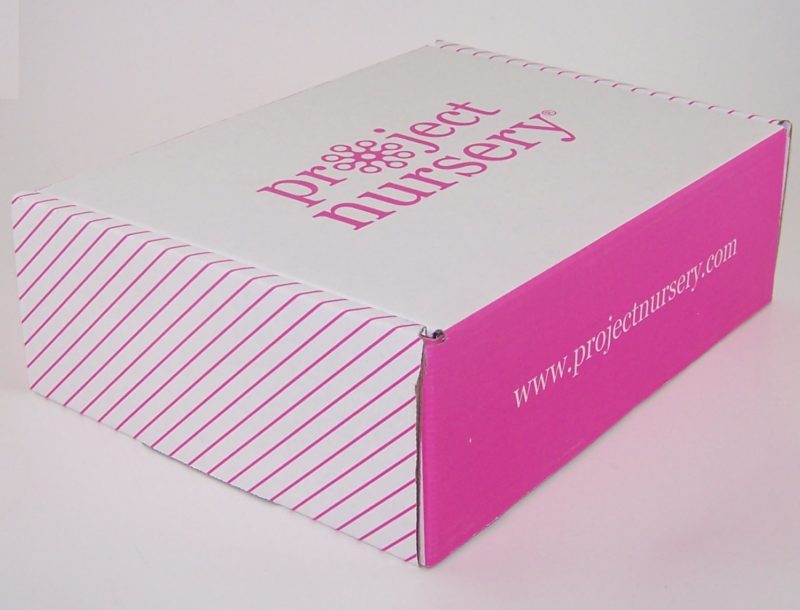

Simply put, it is affordable custom printed packaging because we take some of the steps out of the process and use standard available tooling whenever possible, saving our clients time and money. What’s the difference? When making die cut mailer boxes, custom...

by Dennis Salazar | Mar 21, 2014 | Sustainable Perspective, Inside Sustainable Packaging

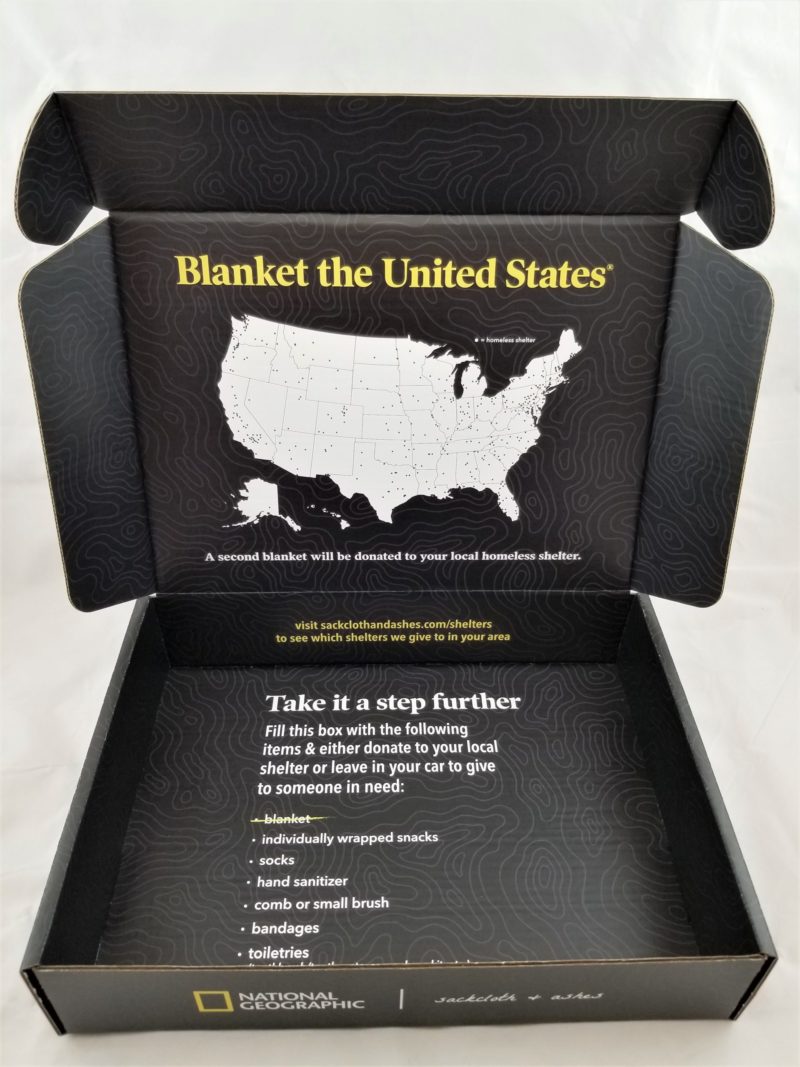

We are widely known for the beautiful custom printed boxes we help our customers create. We have become very proficient at utilizing the standard flexographic print process to its maximum potential to produce unique, eye catching and colorful results. However, what...