by Dennis Salazar | Oct 11, 2017 | Information Center, Sustainable Products

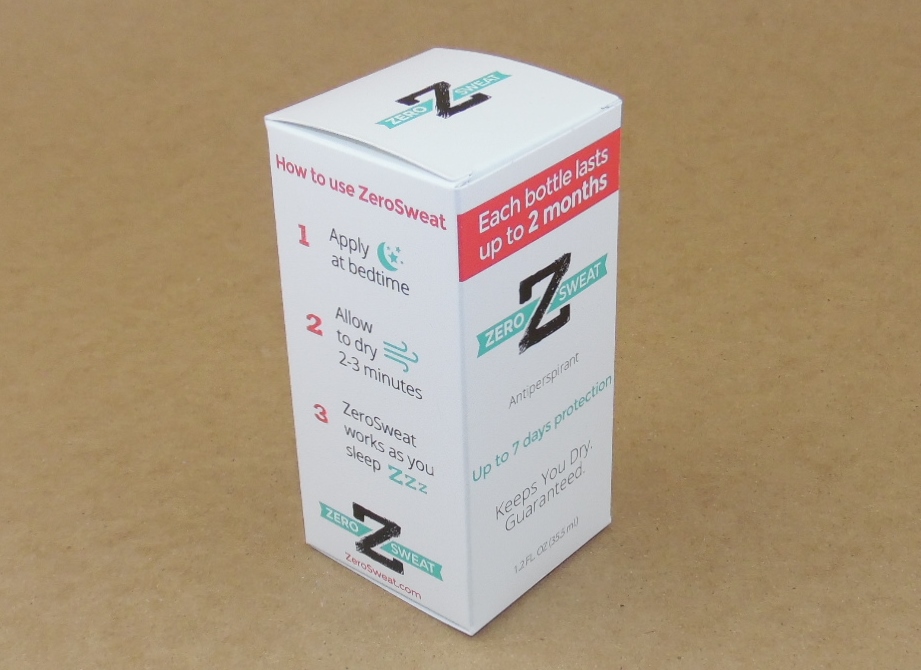

The Difference Between Boxes and Cartons The packaging industry is filled with a variety of terms; some are interchangeable, and some are not. There is also a lot of information available on the internet and not all of it is accurate so we are not surprised when we...

by Dennis Salazar | Oct 1, 2014 | Sustainable Perspective

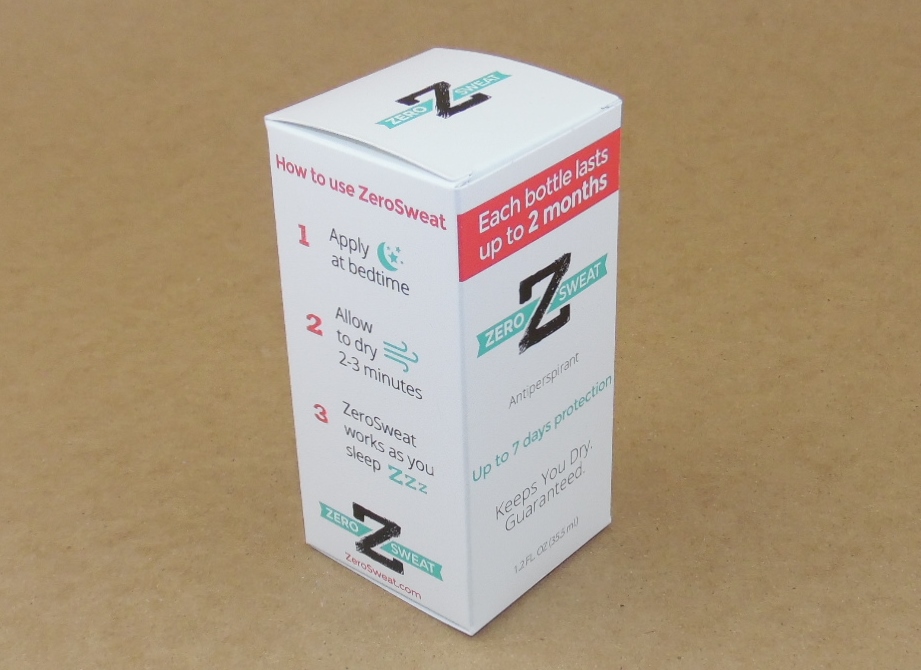

As a result of dramatically increased shipping rates and costs, many shippers today are looking for ways to reduce the overall package weight in an effort to reduce the shipping cost. Being over or under a particular weight (for example, one pound) can make a shipping...

by Dennis Salazar | Aug 29, 2014 | Sustainable Products

Most of our best blog posts are a result of great questions asked by active and potential customers. Our thought has always been, if one person out there is wondering about this, there are likely others with the same question or concern. This is one of those posts...

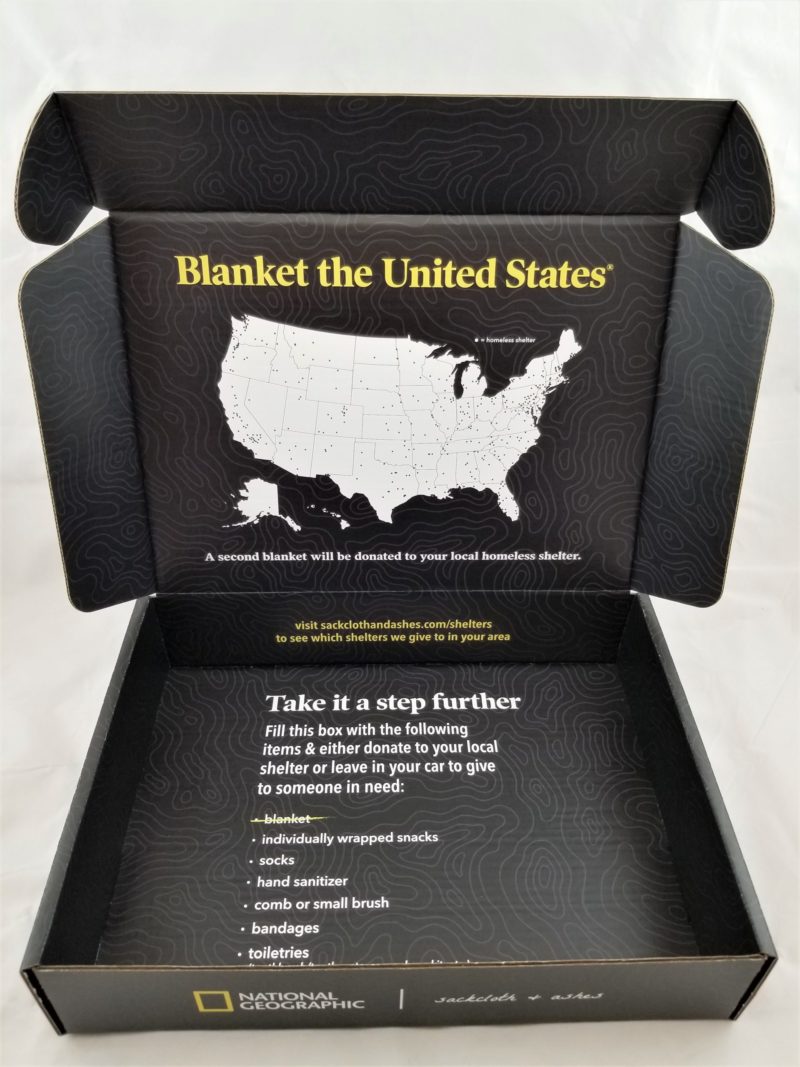

by Dennis Salazar | Mar 21, 2014 | Sustainable Perspective, Inside Sustainable Packaging

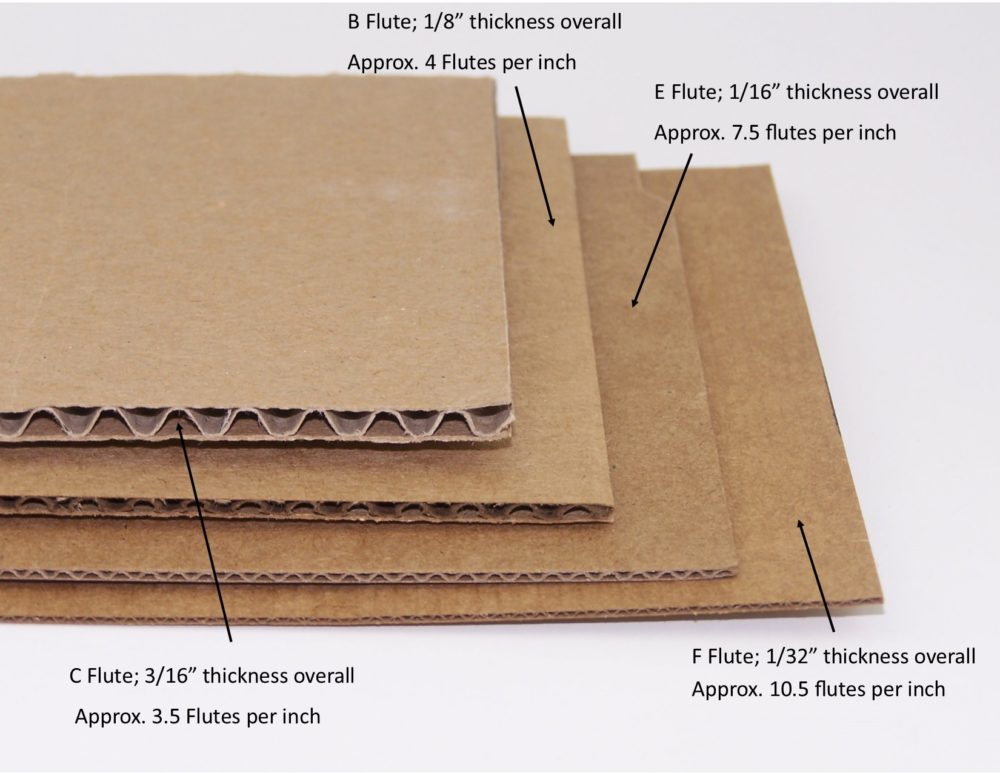

We are widely known for the beautiful custom printed boxes we help our customers create. We have become very proficient at utilizing the standard flexographic print process to its maximum potential to produce unique, eye catching and colorful results. However, what...

by Dennis Salazar | May 1, 2013 | Inside Sustainable Packaging, Salazar News

From our “don’t blame me, I’m only the messenger” department, it appears there is another substantial corrugated price increase headed our way. We are not in favor of an increase at a time of apparent economic recovery, but the indicators are strong enough that we...