by Dennis Salazar | Mar 14, 2022 | Information Center, Sustainable Products

Internal Packaging Solutions for DTC Products This post reminds me of one of my favorite movie lines of all time. It comes from the 1967 classic movie, Cool Hand Luke, when Captain, played by Strother Martin proclaims, “What we have here…is a failure to communicate”....

by Dennis Salazar | Feb 13, 2018 | Sustainable Perspective, Information Center

Box Insert Options for D2C E-commerce Packaging A quick search on the internet will confirm that there are many companies that sell boxes. Online catalog houses and retailer providers ranging from office supply stores to truck rental facilities all sell boxes in their...

by Dennis Salazar | Jan 16, 2017 | Sustainable Perspective, Information Center

The worst possible customer experience is for an eagerly awaited product to arrive damaged or broken. In addition to having a very disappointed customer, you also have to deal with product replacement, which can make a profitable order very unprofitable, very quickly....

by Dennis Salazar | May 9, 2012 | Sustainable Products

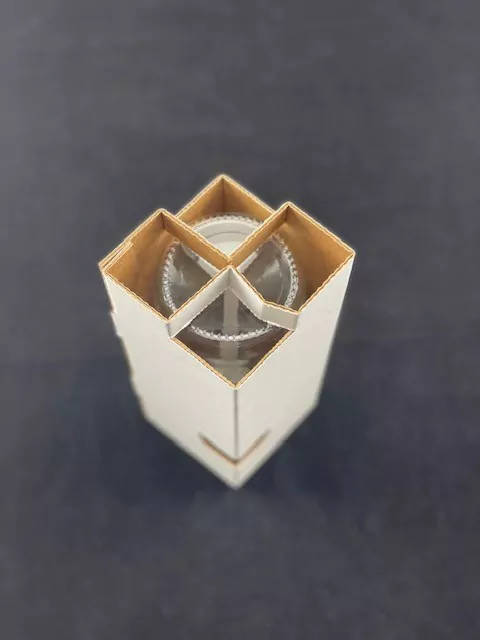

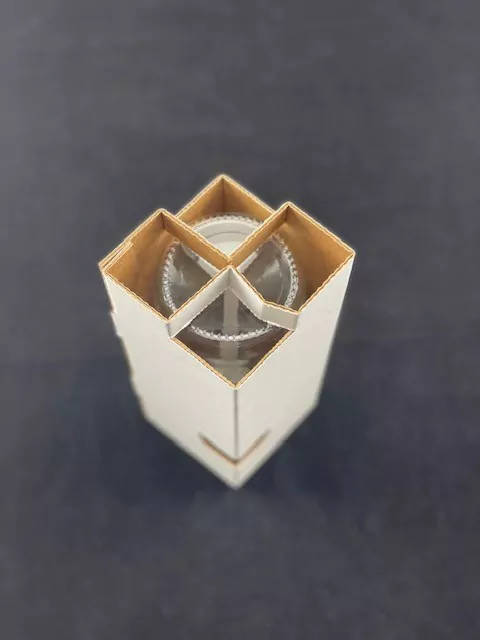

Corrugated inserts to hold and protect a product within a mailer shipping box are usually a great packaging solution. In most cases, they reduce or eliminate the need for additional protective packaging products such as foam, paper or bubble packaging, and the labor...

by Dennis Salazar | Sep 30, 2011 | Inside Sustainable Packaging

Corrugated partitions are an excellent green packaging solution because, just like corrugated boxes, they typically have a high recycled content, are reusable, 100% recyclable/repulpable, biodegradable and even compostable. Also, when they are designed and used...