by Dennis Salazar | Feb 13, 2018 | Sustainable Perspective, Information Center

Box Insert Options for D2C E-commerce Packaging A quick search on the internet will confirm that there are many companies that sell boxes. Online catalog houses and retailer providers ranging from office supply stores to truck rental facilities all sell boxes in their...

by Dennis Salazar | Jul 19, 2017 | Sustainable Perspective, Information Center

How many different size e-commerce shipping containers do you really need? They say variety is the spice of life but in packaging, it can hurt your bottom line if the wrong decision is made. The typical e-commerce shipper has two options: Utilize more, different sizes...

by Dennis Salazar | Jul 11, 2017 | Information Center, Sustainable Products

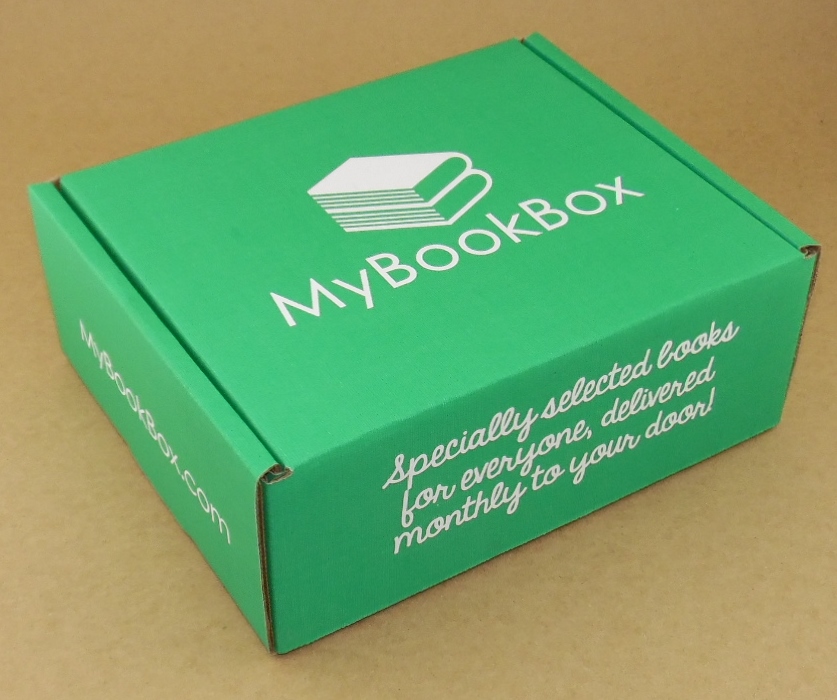

E-Commerce and Subscriptions Packaging for Books A few decades ago I recall listening to a speaker warning we were heading toward a “paperless society”. Since I was at that time employed by the largest paper and packaging corporation in the world, his message caused...

by Dennis Salazar | Jan 16, 2017 | Sustainable Perspective, Information Center

The worst possible customer experience is for an eagerly awaited product to arrive damaged or broken. In addition to having a very disappointed customer, you also have to deal with product replacement, which can make a profitable order very unprofitable, very quickly....

by Dennis Salazar | Apr 26, 2016 | Salazar News, Sustainable Products

There are many candle companies out there but few make the products and presentation you will find at www.keapbk.com. Just like there are many packaging companies but few create the high quality, attractive, yet affordable custom printed packaging we do. So perhaps...