by Dennis Salazar | Feb 15, 2021 | Information Center

Would You Use Wooden Packaging? Occasionally, we receive an inquiry for wooden boxes. Usually it is for primary display packaging, rather than secondary shipping packaging. In other words, the “inner” box that is designed to be kept by the consumer, rather than the...

by Dennis Salazar | Sep 9, 2019 | Information Center

We have made millions of removable and switchable custom inserts for our e-commerce shipping boxes. We believe it is what sets us apart from the many people out there who sell boxes but do not understand inserts or how to design them. As a result, we also...

by Dennis Salazar | Aug 16, 2018 | Information Center

FAQs About Shipping Glass Products for E-commerce Whether your products are natural skin cleansers, cold pressed juices, or hot sauces, if they ship in a glass primary container, they present a unique challenge, but not one we are unfamiliar with. Here are a few of...

by Dennis Salazar | Jul 10, 2018 | Sustainable Perspective, Information Center

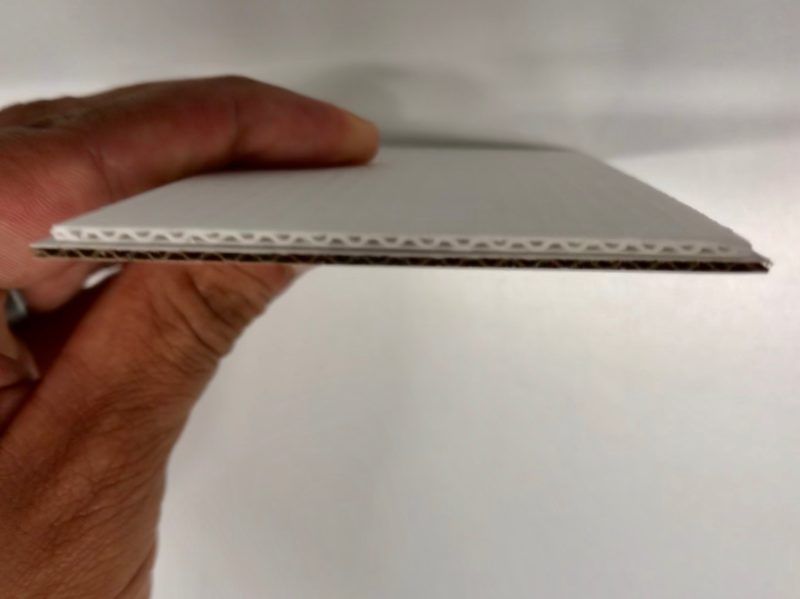

When you look at the cut edge of any corrugated box, even on a double white box that is white inside and outside, you see a brown inner layer called the fluting or medium. That brown center layer is perfectly fine and acceptable for most applications but there are...

by Dennis Salazar | Jun 26, 2018 | Information Center

FAQ for E-commerce box Inserts for Interior and Protective Packaging One of the greatest trends we have seen in D2C, e-commerce packaging is the use of internal packaging to protect and display the products being shipped. Arriving in one piece is the beginning of a...