The above question is one of the most baffling in all of DTC packaging, but it really does not have to be. Corrugated board composition is a complex topic, but it can be simplified so that even a first-time box designer and buyer can understand which option is best for their specific application and needs.

Board Grade Options

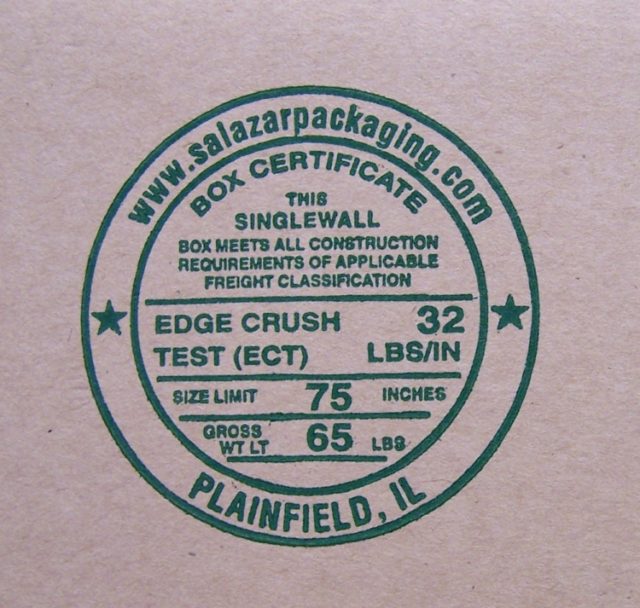

Here is where it gets a little messy. There are two ways of measuring board composition and strength. One is “Edge Crush Test”, otherwise known as ECT, for example, the very popular 32 ECT. That means you can apply 32 pounds of downward pressure on the corners before it caves in and crushes. This is determined by a lab test.

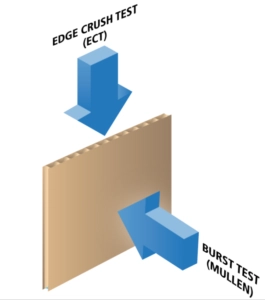

The other, older board rating method is called Mullen and also measures in pounds such as 200# test, or 275# test, measuring burst strength, puncture resistance, and containment. It is as much about keeping potential damage in as it is about keeping potential damage out. The drawing included in this post does a great job of showing the difference between the two different testing methods. Try this link for more detail.

The other, older board rating method is called Mullen and also measures in pounds such as 200# test, or 275# test, measuring burst strength, puncture resistance, and containment. It is as much about keeping potential damage in as it is about keeping potential damage out. The drawing included in this post does a great job of showing the difference between the two different testing methods. Try this link for more detail.

Paper Weights and Thickness Used to Make Corrugated Board

Hang in there with me, I promise in the end you will know and understand what really matters for e-commerce packaging purposes.

There are three parts to every corrugated board sheet or box. The inside layer, the outside layer, and the fluting (zig zag) layer in between the two sheets. The variety of board grades is determined by the paper that is used to create each of these three layers.

For example, 200# board is made of 42#-23#-42# layers of paper. Much heavier 275# corrugated board is made from 69#-23#-69# layers of paper. The combined weight of the three different layers of paper determines the Mullen grade.

On the ECT scale, the board weight is all about the total weight and the paper combination can be a variety of different paper thicknesses. For example, 32ECT can be 30-30-30 or 33-23-23. The same would hold true for heavier ECT board combinations such as 44ECT. In other words, it is about the combined total, not the weight of each of the three sheets or layer. This leads to some variations that are not necessarily good for printing. Especially if you want inside and outside print, which a large percentage of our customers do.

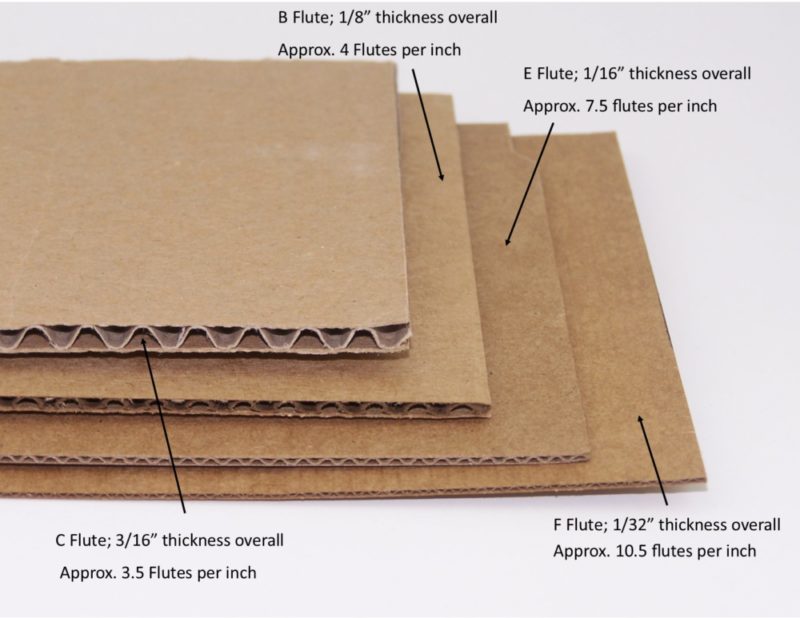

This part is easy, and the drawing shows the variety of flutes that are available. The old adage was “the thicker the flute, the more cushioning and protection the contents receive”. We don’t agree it is quite that black and white and today, most applications include product inserts which can add tremendous strength to the design’s performance. In addition, as the drawing shows, a thin flute has more flutes per inch so in most cases, it provides ample product protection.

C-flute was very popular at one time, then B-flute became widely used standard flute, in part because of a lower cost compared to C. When e-commerce skyrocketed in popularity and volume  around 2005, many customers preferred the even thinner, E-flute. As one customer told us after reviewing B-flute samples we provided, “Don’t you have something less industrial looking?” The additional benefits of E flute include more boxes per pallet, lower storage costs, and easier/faster assembly on the packing line.

around 2005, many customers preferred the even thinner, E-flute. As one customer told us after reviewing B-flute samples we provided, “Don’t you have something less industrial looking?” The additional benefits of E flute include more boxes per pallet, lower storage costs, and easier/faster assembly on the packing line.

E-flute has shorter flutes but more of them because they are closer together. That strength also creates a much better (flatter) printing surface, especially when printing high ink coverage or flood coats. And yes, the box itself has more eye appeal.

What is the Best Board for Your E-commerce Box?

We believe in educating our customers, as much as they want to be educated. After sharing all of the above, the simple answer is the vast majority of our customers’ die cut mailer boxes are made of 200# E-flute board. In second place, in terms of popularity for us is 200# B-flute.

Why not 32ECT? Frankly, 32ECT provides an inconsistent printing surface on both sides of the board. Most of our customers want printing, in some cases, heavy ink coverage complex graphic designs. 200# board is slightly more expensive but, in most cases, we eat that cost difference, just to make sure the customer is happy with the quality of print we deliver. E-flute delivers more than enough strength for most applications. If the product being shipped is a little heavier, we might step up to B-flute and/or 275# test board.

DTC packaging design has become much more about the esthetics as our customers strive for the best unboxing experience. Keep in mind we never sacrifice protection for presentation. Our goal is always to maximize both. (See third related post below.)

There is a solution to every application and our staff has the experience to suggest the right combination for you and your product. Contact us via this web site or call us at 630-551-1700. There is never a charge or obligation for the free consultation.

Related posts:

https://www.salazarpackaging.com/packaging-design-is-not-a-diy-project/

https://www.salazarpackaging.com/popular-micro-flute-board-options-for-e-commerce/

https://www.salazarpackaging.com/balancing-protection-presentation-e-commerce-subscription-boxes/