E-Commerce Packaging FAQs

We like to share questions asked of us multiple times by the inquiries we receive. In close to ten years of blogging we have never run out of topics thanks to the people who come to us for answers. We realized when multiple people ask the same question, there must be others with the same question or concern.

What is the best printing process for me?

That is a difficult question to answer because the response may depend on what you plan to print, how many you want to order, and quite frankly what your budget is for your boxes. Being familiar with different packaging print processes is critical because the design may lead to the process and the process will most certainly impact the cost per box. For example, a design that can be printed using flexographic equipment would cost around half of the same size printed using a litho label or digital print process. The required one-time flexographic print plate cost can be a quick ROI if the box ends up costing a dollar less. Our MOQ is 1,000 so the savings on the boxes is a quick $1,000 which more than covers print plate costs with the first order.

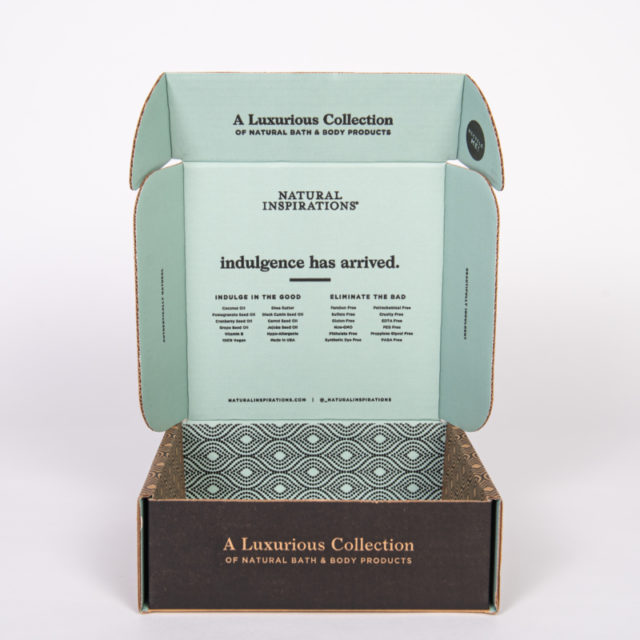

Am I better off printing the inside or the outside of my e-commerce boxes?

Early in the DTC e-commerce boom, around 2010 or so, we were very quick to start recommending minimal, simple outside printing and a more colorful and sophisticated message or design inside. The smaller the box, the more important this is in terms of cost versus impact. A standard shipping label is 4” X 6” so you can see how quickly it can dominate the exterior of any box, especially a smaller one.

Adding printing to the inside will increase the cost but the best reason to not spend a lot of money or add a lot of text and graphics is that most customers don’t read it. Years ago, we were approached by a man who wanted to print his “manifesto” around the perimeter of the box. My response was simple – “you are the customer, and we will print anything you want but from our experience, no one is going to take the time to read it”. When you as a consumer receive a box, the very first thing you look at is the label to make sure it is addressed to you. As soon as you confirm it is for you, you immediately rip the box open to see what is inside. The inside is where you really have an opportunity to create a great impression.

Should I use inserts to protect and present my products or use loose fill?

Should I use inserts to protect and present my products or use loose fill?

I admit in some rare situations, an attractive loose fill product such as shredded kraft or dyed paper can create a “festive” or “surprise gift” look. However, most people who use those packing products eventually move to inserts because inserts look clean and more professional. They do a better job of displaying the product for that all-important unboxing experience.

Which direction we suggest for you will depend on several factors including:

- The type of product you are shipping and its fragility

- The number of product combinations and configurations.

- The cost of your packaging in relationship to product cost.

- The overall purchase quantity of the application.

Simply put if you have fourteen possible product combinations, die cut custom inserts are probably not for you. If your product sells for $19.00 you probably don’t want to spend a dollar for an insert. And if all you need is 200 inserts, the MOQ and die cost are going to be almost impossible to cover.

We have provided some basic, simple answers to some potentially complex questions. That is why it is so important for you to call us at 630-551-1700 or contact us at www.SalazarPackaging.com. We will be glad to provide you with a no cost, no obligation, application review. I also invite you to visit our gallery so you can see a small sampling of the work we have done for other direct to consumer companies.

Related posts:

https://www.salazarpackaging.com/shipping-dtc-product-presentation-vertical-horizontal-or-other/