Many packaging people will tell you these two different types/grades of corrugated board are identical and interchangeable but that is not always true. Our “no surprises, no disappointments” approach to packaging design always results in well-informed customers whose expectations are met or exceeded.

The visible difference

The fact is that even a trained eye is unlikely to tell the difference between the two substrates by simply looking at them. Most people know corrugated board has three distinct layers of paper. The inner sheet, the outer sheet and the “crinkled” fluting (medium) that is sandwiched between the two flat sheets. If you look and compare the two boards side by side, there appears to be no difference unless you are blessed with micrometer-like vision permitting you to see in millimeters which may be the difference between the inner layer and the outer layers.

Board is typically measured and graded by the manufactured combination of the three paper layers after they are glued together. The actual thickness of each individual layer may differ. As long as the combination satisfies the total grade requirement, each layer can be whatever it needs to be based on what paper is available. For example, routinely the inside layer is made of thinner paper and the outer layer is made of a slightly thicker paper. This is important, as you will read below.

The performance differences

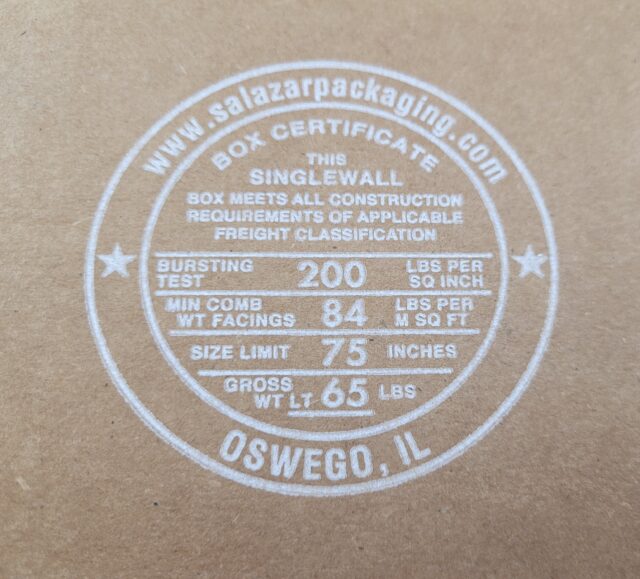

The overall thickness of the board may differ slightly but as we said above, it is not a visible difference. However, if you handled, or squeezed the two different board grades, you may notice the 200# is a little stiffer, feeling more rigid and stronger than the 32ECT. The first related link below provides more detail on how the two boards are measured and tested.

200# test Mullen board is tested to have better puncture resistance so if you are shipping a product that is heavier and may shift in transit, puncture resistance is probably more important than the stacking strength of an ECT measured board. When creating DTC or e-commerce boxes, Mullen board has two other important advantages:

Printability differences:

If you are printing using a flexographic print process, a thicker layer of paper will ALWAYS print better. Good printing begins with a good substrate since you are physically “pressing” the ink onto the board. If you want both sides of a shipper box, having good paper inside and outside is really not optional, it is a requirement. We spec the board for our customers, to their specific application and print requirements.

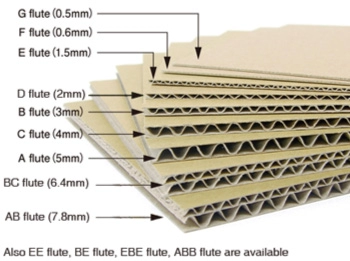

The majority of our die cut mailer boxes are E-flute because it looks less industrial compared to thicker B-flute. Customers usually prefer the cleaner, less bulky look of E-flute, especially when shipping products like pharmaceuticals and personal care products. A better, higher quality board enables you to reduce the board fluting. The flutes are smaller, but there are more of them, so you have a stronger, flatter board which coincidently also prints better.

Flute size –

The majority of our die cut mailer boxes are E-flute because it looks less industrial compared to thicker B-flute. Customers usually prefer the cleaner, less bulky look of E-flute, especially when shipping products like pharmaceuticals and personal care products. A better, higher quality board enables you to reduce the board fluting. The flutes are smaller, but there are more of them, so you have a stronger, flatter board which coincidently also prints better.

Cost differences –

Don’t let anyone tell you that 200# test board is much more expensive, because it is definitely not. The actual cost difference may be a few percentage points, or on most boxes, a few cents. If using a better board makes it possible to reduce board fluting from B to E, the savings in shipping and storage will more than offset any additional cost of upgrading your board. When you add increased protection, and/or enhanced printed graphics, 200# board can be a bargain.

How to create a better e-commerce box?

I hope this post helps you to understand why we specialize in custom printed packaging and how you can benefit from our decades of experience. To learn more, or to discuss your specific needs, please call me or one of our branded packaging advisors at 630-551-1700. You can also contact us through this web site.

These days there are many companies who claim to produce exceptional DTC or subscription boxes. Very few of them know the business and process, as well as our team does. A brief conversation with us and you will realize the difference.

Related posts:

https://www.salazarpackaging.com/e-commerce-packaging-preproduction-and-postproduction-costs/

https://www.salazarpackaging.com/custom-e-commerce-packaging-rest-easy-weve-got-this/